Cold Marking with UV Lasers: Why It's Revolutionizing the Industry

Laser marking has long been a beacon of precision and efficiency in materials processing and manufacturing. Traditional laser marking techniques, which use heat to etch designs or information onto materials, have been the backbone of many industries, ensuring everything from the serial numbers on industrial parts to the intricate designs on jewelry. However, a new contender has entered the arena with technological advancements: cold marking with UV lasers.

Cold marking is not just a buzzword but a significant step forward in our understanding of laser marking. Instead of relying on heat, UV lasers use an absorbing wavelength that marks materials without the thermal stress typically associated with traditional methods. UV laser technology has transformative implications for industries, especially heat-sensitive or precious materials.

In this article, we'll delve deep into cold marking, contrasting it with traditional laser marking methods and uncovering why it's rapidly becoming the industry gold standard.

What is Cold Marking?

As the name suggests, cold marking departs from traditional laser marking methodologies that use heat to create marks. Instead of using thermal processes for etching or engraving, the cold marking harnesses the unique properties of UV (ultraviolet) lasers to produce high-contrast, detailed markings without elevating the temperature of the target material.

At the heart of this technology is the UV laser's specific wavelength, typically around 355 nm. This highly absorbent wavelength lets the material capture the laser's energy more effectively. The result? A marking process that doesn't rely on heat but on the photochemical reaction induced by the UV laser. This reaction causes a change in the material's surface, creating clear and distinct marks.

But why is this significant? The absence of heat ensures no risk of melting, burning, or distorting the material. For industries and applications where the integrity of the material is paramount – think medical implants or aerospace components – this is a game-changer. It means materials retain their original properties, ensuring safety and longevity. In essence, cold marking has redefined the boundaries of laser marking, offering a technique that's gentle on materials and incredibly precise.

Benefits of Cold Marking with UV Lasers

The shift towards cold marking with UV lasers isn't just a technological novelty but a move driven by tangible benefits catering to a broad range of industries. Let's unpack some of these advantages:

Precision and Detail

UV lasers, with their innate ability for fine detailing, can achieve intricate designs and inscriptions without compromising clarity. This is especially beneficial for industries like jewelry or electronics, where detailed markings on small components are crucial.

Material Integrity

One of the standout perks of cold marking is preserving material integrity. Without the heat stress of traditional methods, materials remain unchanged—no warping, burning, or discoloration. This is essential for industries where the material's structural or aesthetic integrity is paramount, such as aerospace or luxury goods.

Efficiency and Speed

Cold marking is often faster than its heat-based counterparts. The UV laser's ability to mark in a single pass without cooling means quicker turnaround times, optimizing production lines.

Low Operational Costs

With reduced energy consumption and no need for consumables or regular maintenance, UV laser marking can lead to significant cost savings in the long run.

Versatility

Cold marking's gentle approach makes it suitable for various materials, from delicate plastics to metals. Industries that previously had to be cautious about laser marking due to material sensitivity now have a viable solution.

Environmentally Friendly

With lower energy consumption and no need for consumables, UV laser marking is a greener alternative, aligning with the growing emphasis on sustainable manufacturing practices.

The benefits of cold marking with UV lasers extend beyond technical aspects. They represent a holistic advancement in laser marking technology, offering industries a precise, efficient, and eco-friendly method.

Traditional Laser Marking vs. Cold Marking with UV Lasers

Laser marking, a staple in industries ranging from jewelry to aerospace, has seen a paradigm shift with the advent of cold marking with UV lasers.

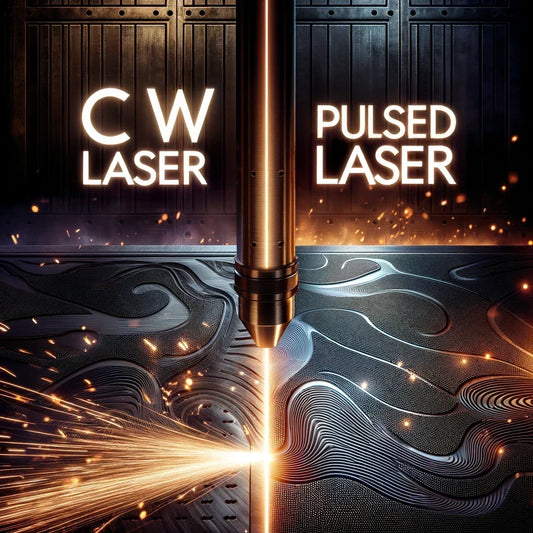

Traditional Laser Marking

Traditional methods employ infrared or green lasers, using heat to inscribe materials. While effective, they come with challenges: potential material warping, discoloration, and the risk of burning or melting, especially with delicate items.

Cold Marking with UV Lasers

On the other hand, cold marking leverages UV lasers to induce a photochemical reaction, creating marks without heat. This approach is safer for various materials and offers greater precision, especially for intricate designs.

Traditional Laser Marking vs. Cold Marking

|

Feature |

Traditional Laser Marking |

Cold Marking with UV Lasers |

|

Method |

Heat-based |

Photochemical |

|

Risk of Material Damage |

Moderate to High |

Minimal |

|

Precision |

Moderate |

High |

|

Suitability for Delicate Materials |

Limited |

Wide-ranging |

|

Energy Consumption |

Higher |

Lower |

|

Speed |

Variable |

Typically Faster |

|

Application Range |

Limited by Heat Sensitivity |

Broad, including heat-sensitive materials |

Industries Transformed by Cold Marking & Case Studies

The proliferation of cold marking with UV lasers has dramatically impacted various industries. Here, we spotlight five sectors that have been notably transformed and present a case study for each to underscore the tangible benefits of this revolutionary marking method.

Jewelry Industry

Case Study: Diamond Delight Jewelers

Challenges: Due to heat, traditional marking methods risked damaging precious metals and gemstones. Detaire often needed to be more intricate and accurate, potentially affecting the jewelry's value and appeal.

Transition to Cold Marking: The jeweler retrained its staff over three months after investing in UV laser marking technology.

Results and Benefits: The precision of cold marking meant designs were more intricate, enhancing the jewelry's value. No heat meant no risk of damaging precious gemstones. As a result, customers highlighted improved craftsmanship in the product reviews, which led to more sales. In addition, quicker marking processes reduced production times by 20%. These two factors boosted the overall business growth of Diamond Delight Jewelers.

Electronics Industry

Case Study: MNVision Electronics

Challenges: Traditional methods often cause heat damage to sensitive components, leading to product waste and increased costs.

Transition to Cold Marking: MNVision integrated UV laser marking into its production line, with initial tests ensuring component safety.

Results and Benefits: Product waste was reduced by 18% with no heat damage—more precise marking improved product traceability, enhancing quality control. Moreover, a faster marking process optimized the production line, leading to a 10% increase in monthly output.

Medical Devices

Case Study: VitoAid Medical Instruments

Challenges: Traditional marking methods compromise sterility, and heat could alter the material properties of surgical tools.

Transition to Cold Marking: VitoAid transitioned over six months, ensuring all UV-marked tools met medical industry standards.

Results and Benefits: Cold marking ensured tools remained sterile, reducing contamination risks. The longevity of tools increased as material properties remained unchanged. This change also improved brand reputation, with many hospitals prefer UV-marked, high-quality tools.

Aerospace Industry

Case Study: LitFly Components

Challenges: Heat-based marking could affect aerospace parts' structural integrity, a risk in a sector where safety is paramount.

Transition to Cold Marking: LitFly phased out old methods over a year, rigorously testing UV laser-marked components.

Results and Benefits: The non-thermal method ensured parts maintained their structural integrity. More precise markings improved traceability and compliance with aerospace standards. Production efficiency increased by 12%, with quicker marking and reduced material waste.

Automotive Industry

Case Study: AllMax Motors

Challenges: Traditional marking could alter the properties of automotive parts, potentially affecting vehicle performance.

Transition to Cold Marking: AllMax piloted UV laser marking on select production lines before full-scale implementation.

Results and Benefits: The transition led to parts with consistent quality, improving vehicle performance. Cold marking's efficiency reduced production bottlenecks, leading to an 11% increase in quarterly production. The clear markings also enhanced recall processes when needed, ensuring better customer safety.

You can find out more about UV laser marking machines applications in our guide.

Conclusion

The spread of cold marking with UV lasers means more than technological progress; it embodies an industry-wide shift towards greater efficiency, accuracy, and quality. This method has changed standards in every industry, reducing property damage and improving accuracy, from intricate jewelry to high aerospace standards.

For businesses, the transition to UV laser marking means staying up-to-date and providing a competitive edge. It is a game changer that promises improved product quality and streamlined operations. UV laser marking is a beacon of innovation and excellence in an ever-evolving industrial environment.

On our website you can purchase 3W UV laser and 5W UV laser machines. Feel free to contact our experienced customer support if you need any assistance.