3W UV Laser Marking Machine

3W UV Laser Marking Machine

Couldn't load pickup availability

Product Description

Product Description

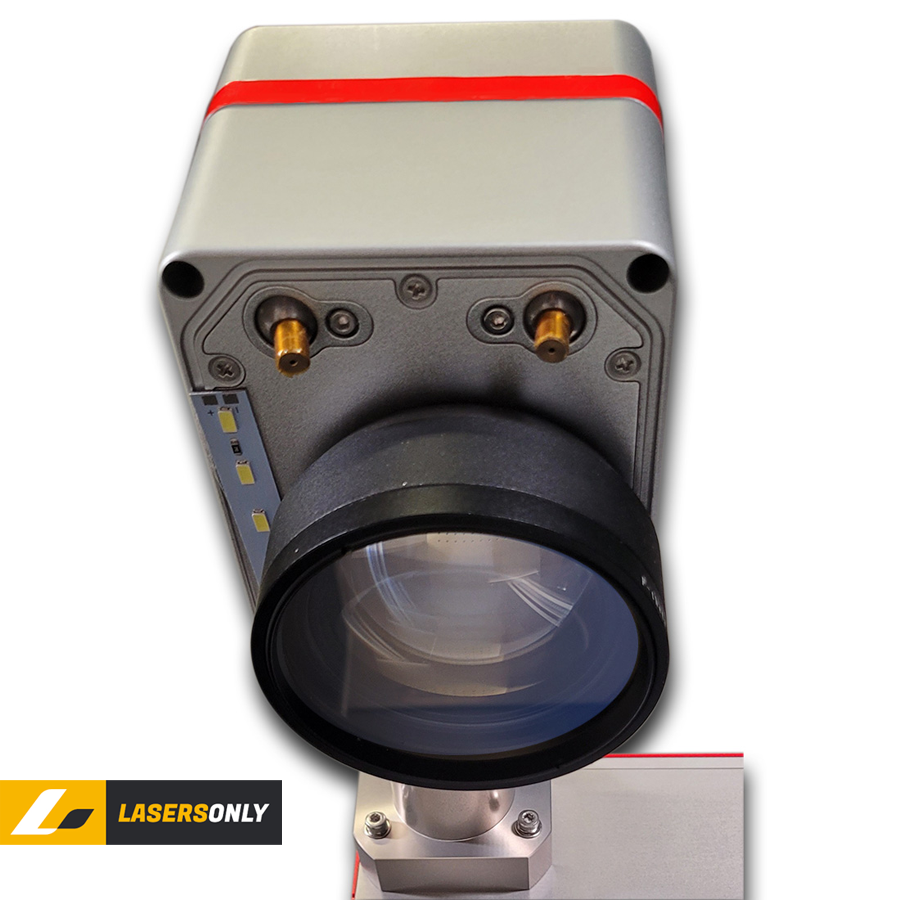

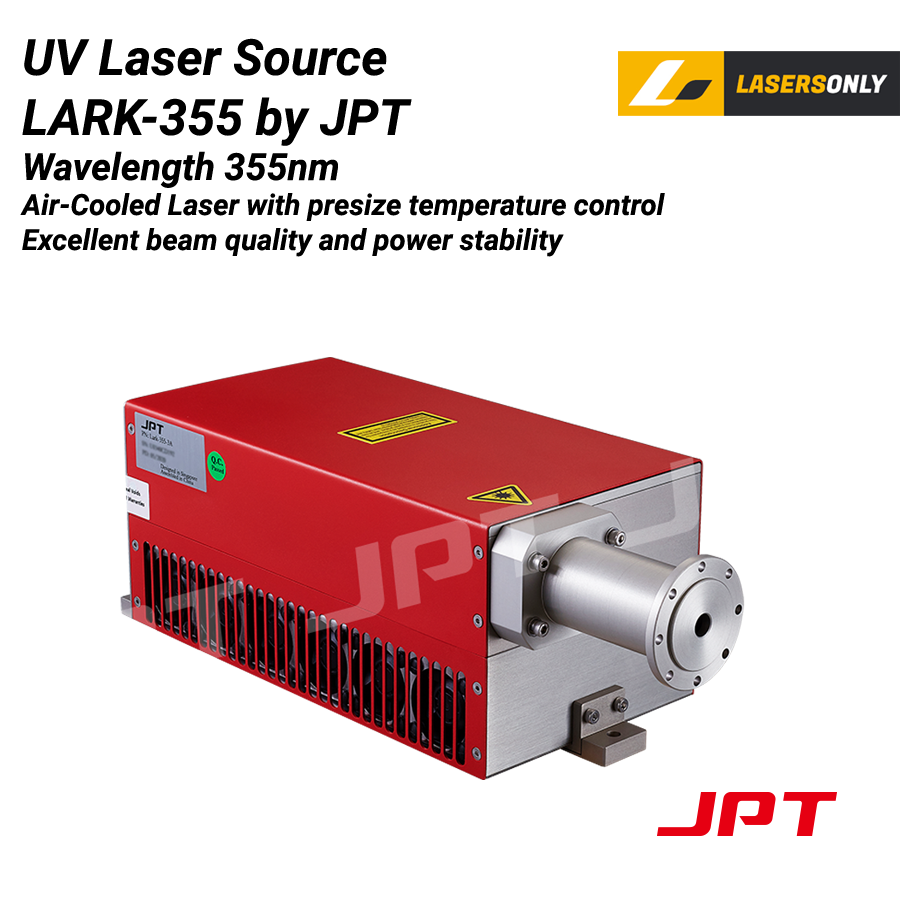

3W UV lasers use a highly absorbent wavelength of 355 nm and are better captured by virtually all materials than other wavelengths and marking techniques. 3W UV laser requires less power to produce a clear mark. Less power and a high absorption rate allow 3W UV lasers to perform "cold marking," ensuring that no extra heat stress is applied to materials, including those with high reflectances, such as gold, silver, and copper.

Thus it produces less soot and burrs caused by the typical marking process, 3W UV laser marking ensures a high-quality, high-contrast mark in one application. 3W UV laser can generate greater contrast for more appealing aesthetics and improved readability and precision. The 3W UV galvo lasers are as fast as other fiber lasers on the market and significantly faster than their gantry-based counterparts.

Shipping & Returns

Shipping & Returns

Free USA Shipping

We stock the most popular machines in our warehouse in Jersey City, NJ.

We ship equipment on the same or the next day after receiving the order. We inspect the package and test the laser before sending it out to the customer.

We ship by UPS Ground service or FedEx. Coast-to-coast shipping usually takes 4-5 days.

30-Days Return Policy

We have a 30-day return policy, which means you have 30 days after receiving your item to request a return.

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at support@lasersonly.com. If your return is accepted, we’ll send you instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

The customer is responsible for expenses associated with return shipping.

- Free US Shipping

- 2-Year Warranty

- Lifetime Support

Apply Today

Financing Available

Use one of our reliable partners to finance your purchase. Learn more about available options and payment terms.