1500W SUP Fiber Laser Cleaning Rust Removal Machine

1500W SUP Fiber Laser Cleaning Rust Removal Machine

Couldn't load pickup availability

Product Description

Product Description

1500W Fiber Laser Rust Removing / Cleaning Machine can remove rust, paint, oil, and oxide film on all metal and some non-metal surfaces and clean black ash, carbon deposition, and oil stain on the surface of parts after welding. Laser cleaning is a preferred method to prepare surfaces; it significantly increases adherence in powder coating and painting, improves cleaning before and after welding, and it’s a perfect tool for restoration projects.

Laser Cleaning equipment can be used on various metal substrates (titanium alloys, aluminum alloys, high-temperature alloys, stainless steel, carbon steel, etc.), semiconductor materials, etc., or fully automatic cleaning systems. The machine can be used in many industries, such as aviation, aerospace, rail transit, shipbuilding, automobile, electronic industry, and many more. They could be efficiently used for rust removal on bridges, and large metal facilities, such as stadiums, factories, and many other metal structures.

A laser cleaning machine is a great addition to any modern manufacturing and fabrication shop. Laser cleaning utilizes the high-energy laser source to perform a non-contact cleaning process without damage or deformities to the treated substrate, providing high efficiency and an environmentally safe work environment. The non-contact method ensures maintenance-free and cost-effective operation without costly and hazardous consumables. This equipment significantly improves the quality and effectiveness of surface cleaning operations. This process is an ideal choice for the new generation of industrial cleaning technology.

Product Features

- Eco-Friendly - Laser cleaning is an environmentally-friendly method; that doesn’t pollute or use hazardous cleaning agents

- Excellent Results - Thanks to the SUP controller and handheld scanner technology, producing laser beams up to 300mm wide and outstanding cleaning effects

- User-Friendly - Quick setup and easy operation with a short learning curve by experienced and novice technicians

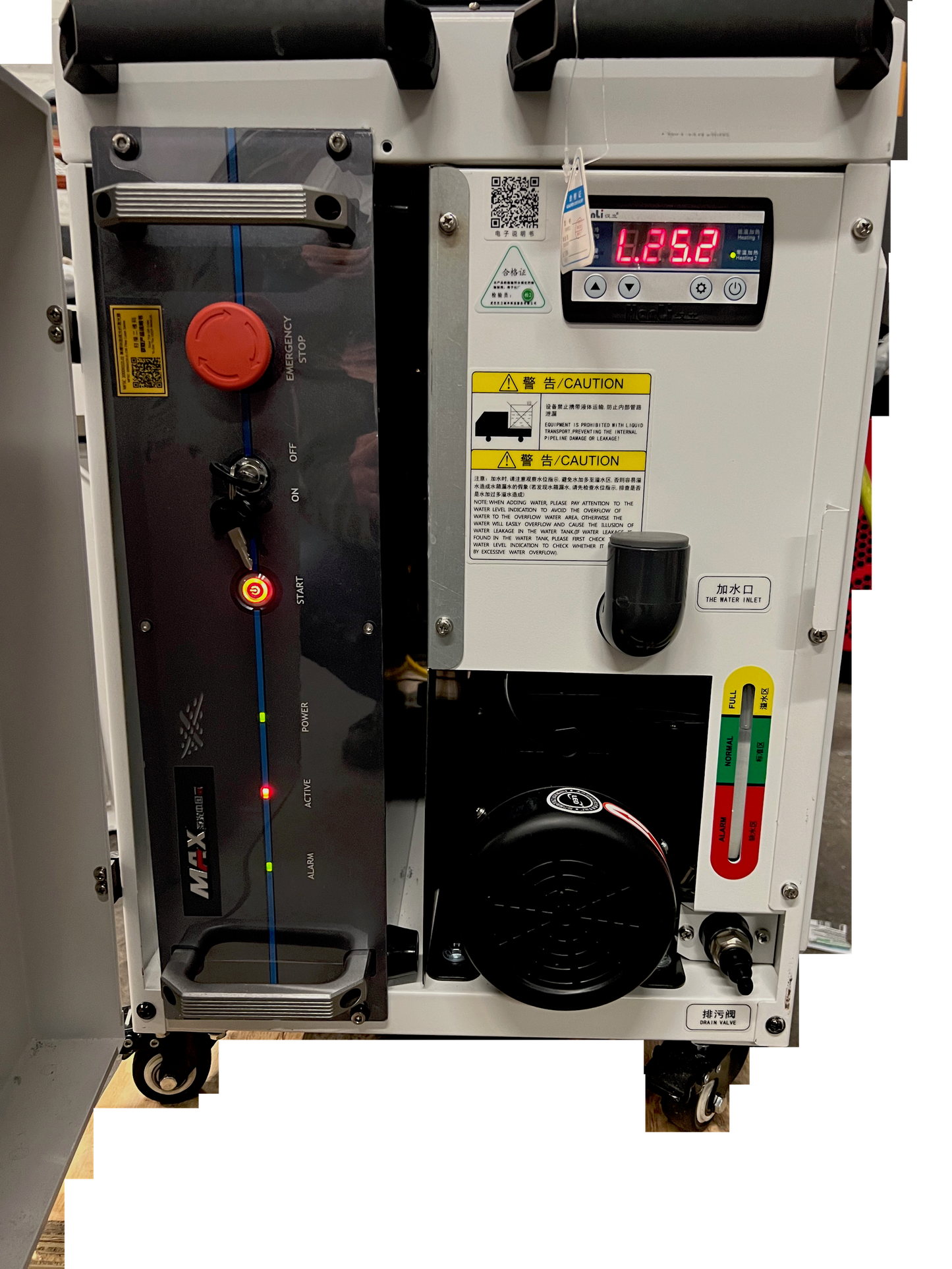

- Usability - Operation convenience thanks to the compact design with built-in water chiller and standard power requirements - single phase 220V

- Portability - Easy Reach thanks to the 33 feet long fiber optics cable and rolling cabinet for effortless transportation

- Free Maintenance - Thanks to the long lifespan of the laser source and no consumables

- Versatile Applications - Laser cleaning technology can be used for various material processing needs within different industries such as aerospace, automotive, military & defense, power generation, nuclear facilities, and maintenance & repair facilities

Product Specification

| Model No. | CW1500-FLC3-RUIDA |

| Laser Power | 1500W |

| Power Stability | ±1% |

| Laser Wavelength | 1080 ± 10 nm |

| Laser Mode | Continuous Wave |

| Laser Beam Quality | < 1.5 |

| Power Consumption | 4.5 KW |

| Power Supply | AC 220V Single Phase |

| Fiber Optics Cable | 33 feet |

| Cooling Method | Integrated Water Cooling |

| Dimensions | 9030*600*1200mm |

| Weight | 195KG |

| Working Environment | 5~35℃, 5%~75% |

Laser Source: Technical Parameters

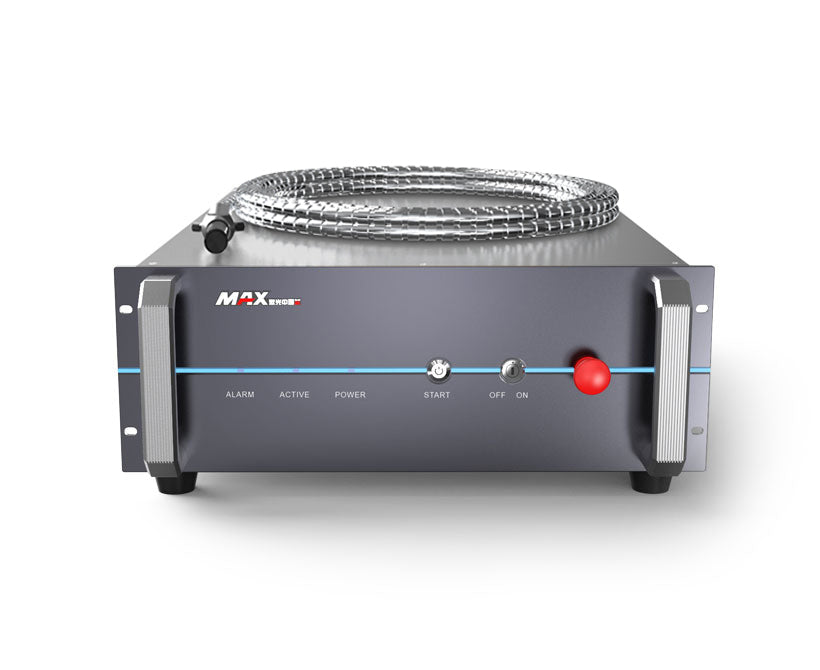

Maxphotonics 1000X-1500X-2000X SINGLE MODULE CW FIBER LASER

MFSC Single Module CW Fiber Laser Source has excellent beam quality and high stability, with a compact structure and water-cooling method.

Product Advantages

- Stable, reliable, and energy-saving operation

- Maintenance-free, moisture-protected construction

- Precision thanks to superior beam quality

- Long product life with a rigid, sealed design

Technical Parameters

|

Models

|

MFSC-1000X

|

MFSC-1500X

|

MFSC-2000X

|

|

|

OPTICAL SPECIFICATIONS

|

||||

|

Nominal Power

|

1000W

|

1500W

|

2000W

|

|

|

Mode of Operation

|

CW/Modulated

|

|||

|

Polarization

|

Random

|

|||

|

Power Tunability

|

10 to 100%

|

|||

|

Wavelength

|

1080 ± 10 nm

|

|||

|

Power Stability

|

±1 %

|

|||

|

Laser Beam Quality, BPP

|

≤1.5 mm x mrad (50μm QBH)

|

|||

|

Modulation Frequency

|

≤20 kHz

|

|||

|

Preview Red Light Power

|

150 μW

|

200 μW

|

||

|

FIBER DELIVERY SYSTEM

|

||||

|

Interface

|

QBH (LOC)

|

|||

|

Length

|

15m standard, other lengths optional

|

|||

|

Diameter

|

50 (25) μm

|

50 (35) μm

|

||

|

Bending Radius

|

200 mm

|

|||

|

ELECTRICAL RATINGS

|

||||

|

Supply Voltage

|

220VAC (-15% to +10%) Single-phase

|

|||

|

OTHER SPECIFICATIONS

|

||||

|

Operating Temperature

|

+10 to +40℃

|

|||

|

Storage Temperature

|

-10 to +60℃

|

|||

|

Humidity

|

10 to 85%

|

|||

|

Cooling Method

|

Water Cooling

|

|||

|

Cooling Medium

|

Distilled water/ Glycol Antifreeze

|

|||

|

Dimension

|

482.6×800×193mm (W×D×H)

|

483×950×193 mm

|

||

|

Weight

|

53(±3) kg

|

57(±3) kg

|

72(±3) kg

|

|

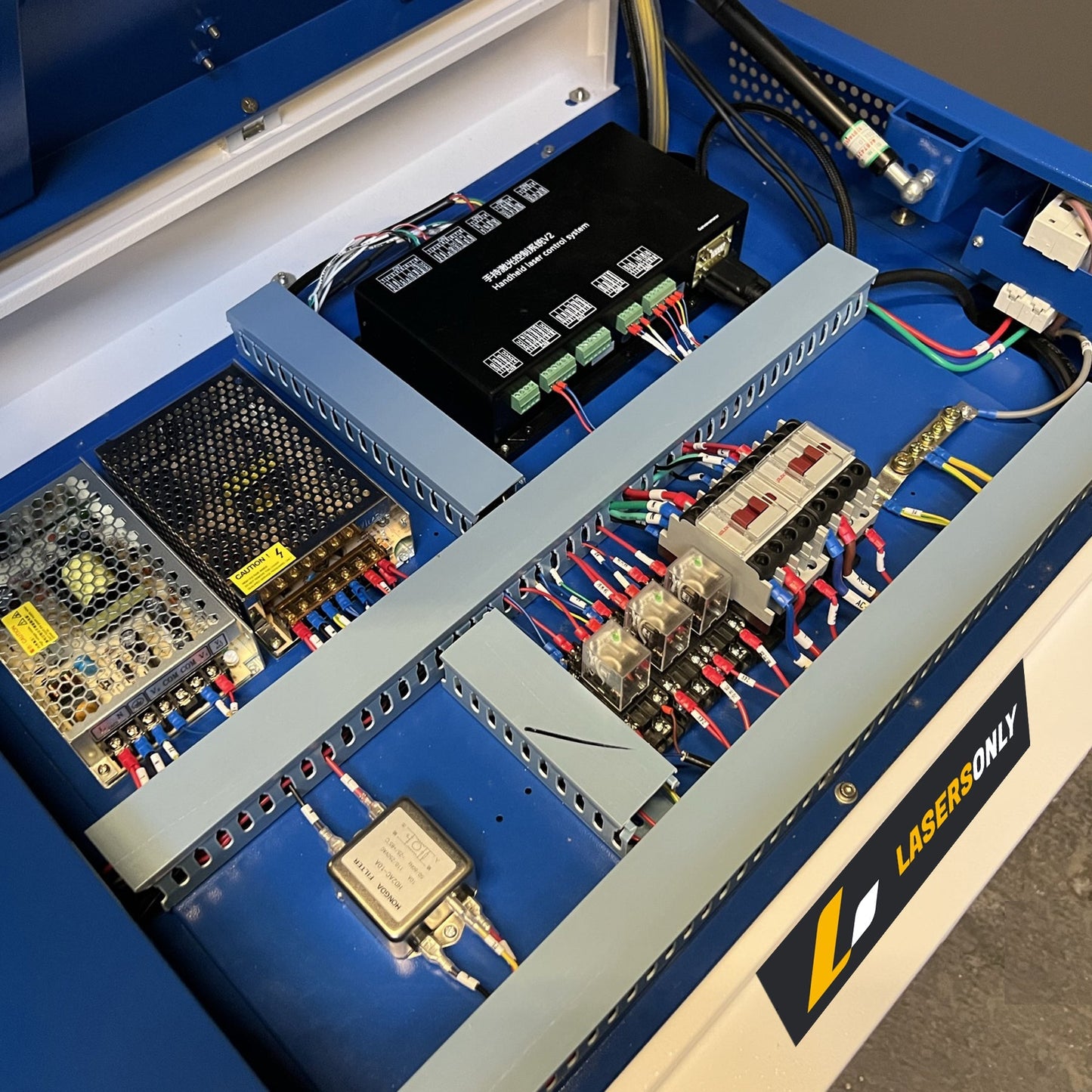

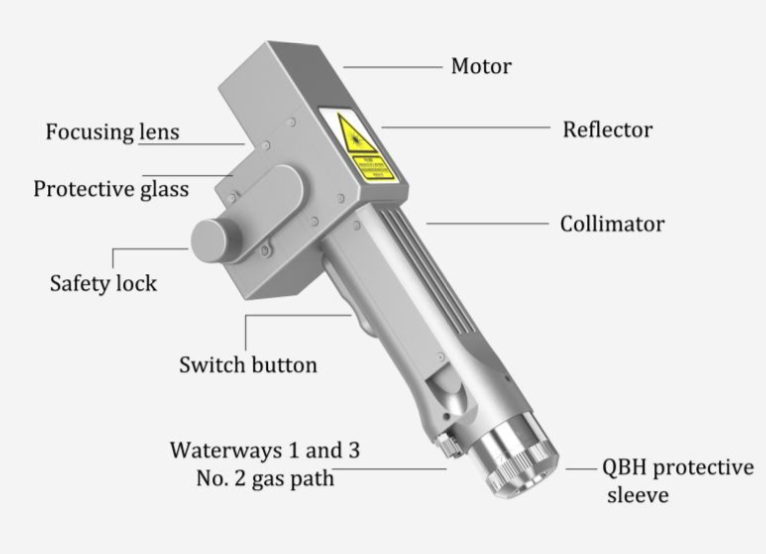

Controller & Laser Gun: Technical Parameters

SUP22C Laser Cleaning Head

SUP22C is an improved version of the SUP21C model with better insulation, stability, and maintenance; it’s lighter and has a more compact design.

- Proprietary control system with multiple safety alarms and automatic power and laser shut-down

- Real-time system monitoring and easy troubleshooting

- Compatible with various fiber laser types

- Lightweight and compact design, easy to operate the handheld gun

- Stable operation and excellent cleaning results

Specifications

| Supply Voltage, V | 220+10%V AC 50 / 60 Hz |

| Placement Environment | Flat, No Vibration, and Impact |

| Working Temperature, C | 10 - 40 |

| Working Environment Humidity, % | < 70 |

| Cooling Method | Water Cooling |

| Applicable Wavelength | 1064nm (+10nm) |

| Applicable Power | < 3000W |

| Collimating Lens | D16*5 / F60 |

| Focusing Lens | D20*3.5 (F400 / F600 / F800) |

| Reflective Mirrors | 20*15.2*T1.6 |

| Protective Windows Specifications | D30*T5 |

| Maximum Support Pressure | 15 Bar |

| Adjustment Range of Spot | +10mm |

| Scan Width-Wash | F400-0~150mm |

| F600-0~225mm | |

| F800-0~300mm | |

| Weight | 0.7kg |

Shipping & Returns

Shipping & Returns

Free USA Shipping

We stock the most popular machines in our warehouse in Jersey City, NJ.

We ship equipment on the same or the next day after receiving the order. We inspect the package and test the laser before sending it out to the customer.

We ship by UPS Ground service or FedEx. Coast-to-coast shipping usually takes 4-5 days.

30-Days Return Policy

We have a 30-day return policy, which means you have 30 days after receiving your item to request a return.

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at support@lasersonly.com. If your return is accepted, we’ll send you instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

The customer is responsible for expenses associated with return shipping.

- Free US Shipping

- 2-Year Warranty

- Lifetime Support

Apply Today

Financing Available

Use one of our reliable partners to finance your purchase. Learn more about available options and payment terms.